PBAT is the main development direction of degradable materials in the future, with a wide range of applications.

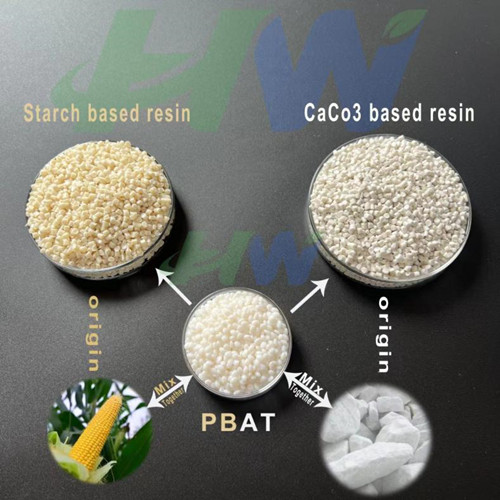

(PBAT. Starch based resin. CaCo3 based resin)

Degradable plastic products include disposable tableware, disposable plastic bags, packaging paper, clothing, agricultural films, 3D printing materials, medical materials, etc; As one of the most promising biodegradable materials, PBAT combines the characteristics of PBA and PBT, with good ductility and elongation at break, as well as good heat resistance and impact performance. PBAT materials can not only be composted but also biodegradable. Among them, the biodegradable garbage bags produced by PBAT are the membrane materials used in the recycling of bio transformed waste in the bio composting garbage center. They are mainly used in: fully degradable packaging bags, fully degradable packaging films; Including pet manure bags, shopping bags, roll up garbage bags, electronic product packaging bags, plastic films, food packaging bags, etc.

Starch based plastics use chemical reactions to chemically modify starch, reducing its hydroxyl groups and altering its original structure, thereby changing the corresponding properties of starch and transforming it into thermoplastic starch. The modified material is mainly composed of a mixture of corn starch and PBAT.

Starch based biodegradable plastics are plastic products made from biodegradable polymer materials such as starch and PBAT. Compared with traditional plastic products, starch based biodegradable plastics have the following characteristics:

1. Biodegradability: Starch based biodegradable plastics can be decomposed by microorganisms into natural substances such as carbon dioxide, water, and organic fertilizers after about 180 degrees in specific environments, without causing environmental pollution.

2. Biocompatibility: Starch based biodegradable plastics have good compatibility with human tissues and do not have toxic side effects on the human body. They can be used in the manufacturing of disposable medical supplies.

3. Processability: The plasticity, stretchability, and surface smoothness of starch based biodegradable plastics are comparable to ordinary plastics, making them easy to process into various shapes.

4. High strength: Starch based biodegradable plastics have high strength and can be used to manufacture lightweight structural parts.

The environmentally friendly properties and good feeding characteristics of starch based biodegradable plastics have made them widely used in multiple fields.

1. Food packaging field: Starch based biodegradable plastic bags, tableware, and food boxes can replace traditional disposable plastic products and have good usage effects. These products can be decomposed by microorganisms after use and will not cause environmental pollution.

2. Agriculture: Starch based biodegradable plastics are widely used in agriculture, such as plastic films, horticultural tools, and greenhouse covering materials used in planting protection. These products can also be naturally degraded after use, with minimal impact on the environment.

3. Medical and health field: Starch based biodegradable plastics can be used to manufacture disposable medical supplies, such as surgical gowns, surgical towels, etc., and can also be used to produce medical packaging materials, etc.

In summary, starch based biodegradable plastics have good environmental performance and broad application prospects, which are of great significance in promoting the development of environmentally friendly plastic products.

A biodegradable material with good blowing performance was prepared using PBAT as the substrate and CaCO3 as the filler. It has high stability, durability, high tensile strength, and improved viscosity, storage modulus, and loss modulus.

Calcium carbonate filled with biodegradable plastics can accelerate the degradation of biodegradable plastics. At the same time, calcium carbonate can be directly utilized as a carbon source by certain inorganic nutrient microorganisms. The organic acids produced by microorganisms during soil activity, as well as the nitric acid and sulfuric acid produced by nitrifying and sulfurizing bacteria, can further improve the solubility of calcium carbonate.

1. Promote degradation: Calcium carbonate particles increase the distance between resin molecules, reduce the force of polymer chain segments, hinder the re crosslinking of macromolecular free radicals, promote the free radical chain breaking reaction caused by photodegradation, and accelerate the degradation of biodegradable plastics.

2. Easy to decompose: Buried in humid environments, calcium carbonate can undergo chemical dissolution, and it is directly utilized as a carbon source by some inorganic nutrient microorganisms.

3. Reduce viscosity and improve fluidity: The surface treated calcium carbonate enhances the viscosity of degradable plastics, improves material fluidity, and reduces energy consumption.