Biodegradable and Compostable

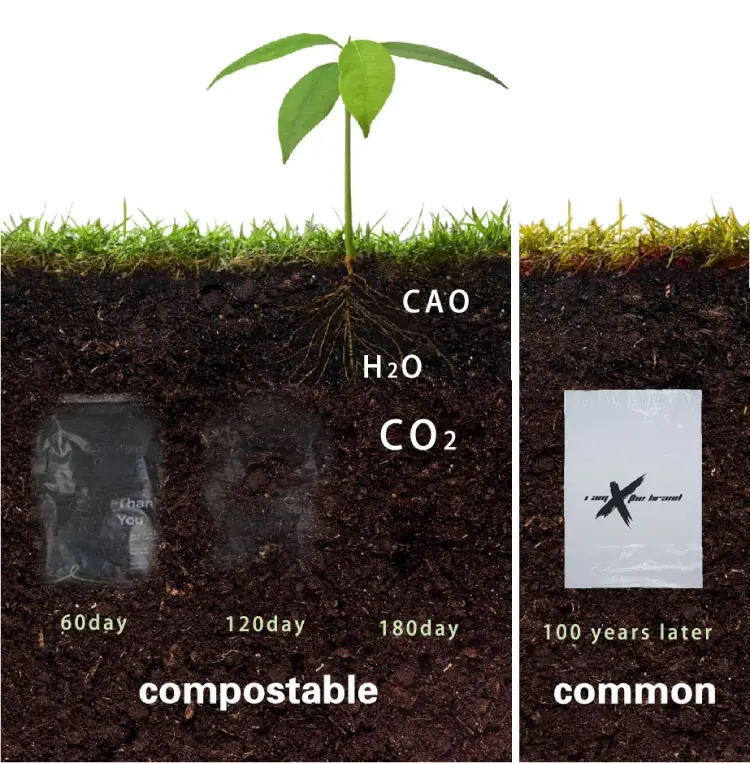

1)PLA is biodegradable under commercial composting conditions and will breakdown within twelve weeks, making it a more environmentally choice when it comes to plastics in contrast to traditional plastics which could take centuries to decompose and end up creating microplastics.

2)The term compostable refers to a product or materials that can biodegrade under specific, human-driven circumstances. Unlike biodegradation, which is an entirely natural process, composting requires human intervention.

During composting, microorganisms break down organic matter with the help of humans, who contribute the water, oxygen, and organic matter necessary to optimize conditions. The composting process generally takes between a few months and one to three years.1 The timing is impacted by variables like oxygen, water, light, and the type of composting environment.

Starch-based biodegradable materials:

Challenges and opportunities

1. Starch is one of the most promising natural polymers because of its inherent biodegradability, overwhelming abundance and annual renewability. Starches offer a very attractive low cost base for new biodegradable polymers due to their low materials cost and ability to be processed with conventional plastic processing equipment. Development and applications of biodegradable starch-based materials has attracted increasingly attention since the well recognized issues of oil shortage and the growing interest in easing the environmental burden due to extensive use of petrochemically-derived polymers. Currently more and more countries have introduced regulations and lows of banning disposable plastics.

2. Bioplastics help manufacturing companies stay competitive by helping to meet rising consumer expectations of sustainability. They are often derived from various biomass sources, the most widely used being starch, which is a natural polymer that can be incorporated in various materials. Starch-based plastics can be used in a variety of applications since they can be incorporated with various petroleum-based polymers or biopolymers to create unique composite materials. These composite materials can then be injection molded or extruded using standard processing machinery.Improving performances and decreasing cost. Reduce pollution, starch based products can be completely degraded to protect the environment.

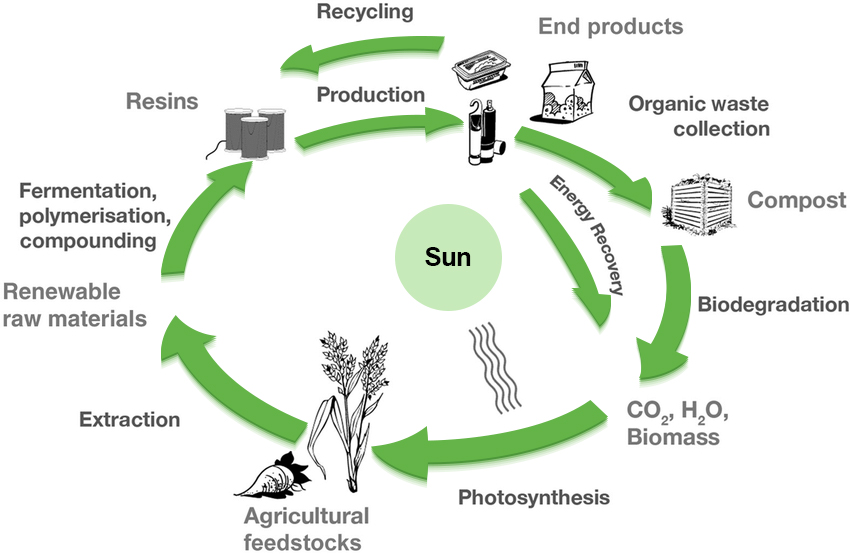

PLA raw materials et Biodegradable plastic

1. PLA is biodegradable under commercial composting conditions and will breakdown within twelve weeks, making it a more environmentally choice when it comes to plastics in contrast to traditional plastics which could take centuries to decompose and end up creating microplastics. PLA is a type of polyester made from fermented plant starch from corn, cassava, maize, sugarcane or sugar beet pulp. The sugar in these renewable materials are fermented and turned into lactic acid, when is then made into polylactic acid, or PLA.

2. Biodegradable plastics are those that can decompose naturally in the environment. The makeup structure of biodegradable plastics makes them easily break down by natural microorganisms, giving an end product that is less harmful to the environment.

As such, biodegradable plastics are perceived to be more eco-friendly due to their environmental benefits, which are hard to deny compared to ordinary plastics.

What is compostable resin made of?

Family of biodegradable & compostable resins made from different starches such as corn, potato, cereals, and other biologically sourced polymers. Compostable resins are designed to run on existing standard industrial equipment, offering the opportunity to completely replace traditional plastics.

Benefits

• Compostable resins can be processed by conventional extrusion, cast film, blown, sheet, extrusion coating, and injection molding lines without extra technological investment.

• Completely biodegradable and compostable. These two properties allow a plastic packaging materials to be recovered through the organic recycling of solid waste (composting and anaerobic digestion) and are certified by the European standard EN 13432, American standard ASTM-D6400