Although the pinyin of plastic injection molding and plastic injection molding is similar, but the process method is very different.

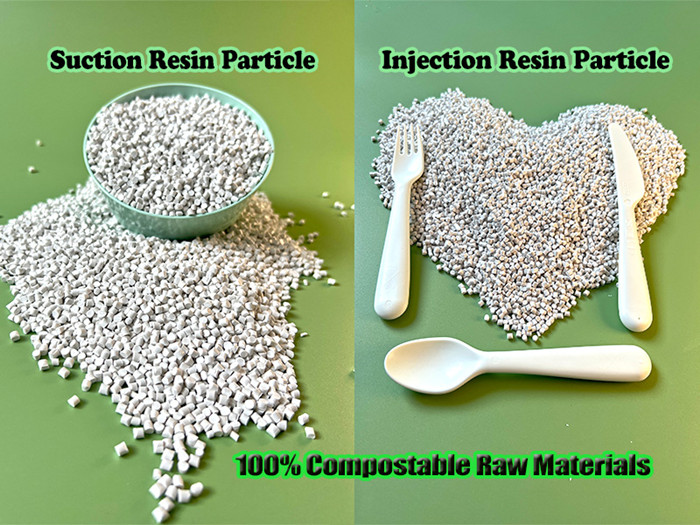

Suction molding is a thermoplastic plastic sheet or sheet of film by heating and softening, air pressure or vacuum will be adsorbed on the surface of the mold to form products.

Injection molding is a kind of plastic heating and melting, injected into the mold, in the mold cooling molding method.

Injection mold has two half-molds, one of which is fixed on the injection molding machine, the other half-mold is moved through the power system of the injection molding machine, when the two half-molds are combined to form a closed mold cavity. At this time, the melted plastic is injected into the mold cavity, after a certain cooling time, the plastic can be solidified into a solid, so as to form the required parts.

Suction molding is the softening of thermoplastic plastic sheets through thermal processing, and then adsorbed on the surface of the mold, thus forming the desired parts. Usually a vacuum is applied to the mold, while curved parts are formed by applying air pressure.

The process characteristics of injection molding and vacuum molding are also different. Injection molding has the following advantages:

1. High production efficiency: hundreds or even thousands of products per minute;

2. High precision: mold design accuracy can reach micron level;

3. Wide range of application: almost all engineering plastics, plastic glass, etc. can be processed;

4. Low cost of small and medium-sized batch production: with the increase of production batch, the cost and price of injection molding processing will also be reduced.

Suction molding, on the other hand, has the following advantages:

1. Low cost: no need for cooling water, injection molding machines and other special equipment, the equipment and devices needed are common and low cost;

2. Simple production process: the production process is relatively simple compared to injection molding, and can make complex shapes, so the production efficiency is higher.

Due to the different production principles, the scope of application of Suction and injection molding is also different.

Suction molding is usually applied to the production of small three-dimensional plastic products, such as plastic bowls, lunch boxes and so on.

Injection molding is applicable to plastic products, such as knives. Fork. Spoon daily necessities.

Suction molding usually requires less initial cost, because it uses thermoplastic polymer sheet, the material is relatively cheap.

Injection molding has a higher initial cost because it requires the use of polymers in powder or granular form and requires more process steps. Injection molding also requires time and money to create molds before production can begin.

There are advantages and disadvantages to both Suction and injection molding. Suction molding makes it easier to achieve displays with special features such as inlays and is generally better suited to producing small batches than injection molding. However, the finished product of Suction molding is usually thinner and less robust than the finished product of injection molding.

Injection molding can produce larger and thicker plastic products and is usually more stable and consistent. However, injection molding is more expensive to create molds and requires more process steps. Additionally, injection molding may require the use of more plastic, resulting in higher production costs.

Suction and injection molding are two commonly used plastic manufacturing processes, and their respective advantages and disadvantages help meet different needs.